It has been my observation that a bunch of folks involved in building-materials salvage are lumber centric.

Ask almost anyone in our business which materials they covet and you will hear something like “Lumber” or “Lumber is what my customers ask for.” I hear this over and over—even from our own employees. But wait, it gets more dramatic once the conversation touches on old-growth lumber, at which point all other topics become extraneous. Old growth lumber is limited in quantity, difficult to get and pleasing to the eye. I get it. Remember, I’m the guy who two months ago wrote The Velvet Crowbar blog entitled, “Musings of a Lumber Hugger.”

But, what about all the other stuff—appliances, bricks, cabinets, doors, windows? There is a demand for those materials too, so let’s look at the markets and advantages of lumber vs. fixtures.

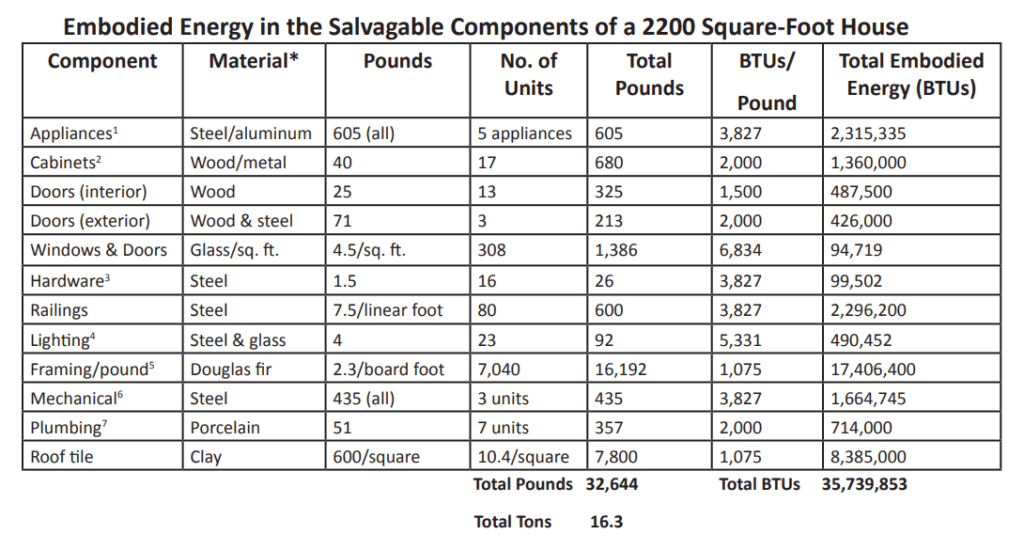

I was recently asked to conduct a 90-minute webinar on Life Cycle Assessment and, consequently, needed to do some research. I decided to focus on embodied energy. The whole notion of the energy it takes to make something intrigued me, especially since TRP was part of a study on the topic by Forest Products Laboratory. My investigation led me to the book, Stewardship of the Built Environment, by Robert A. Young in which he charts building materials and quantifies their embodied energy in BTUs per pound.

Using Professor Young’s research, I looked at my own house as a deconstruction candidate and calculated the embodied energy for each component that would normally be salvaged.

Below is a chart of those materials, their quantity, weight and the embodied energy in each. What becomes apparent is that while lumber has the lowest embodied energy per pound, the total energy in the quantity of lumber salvaged is the highest of all the materials that would normally be salvaged. Yet, it only totals 49% of the embodied energy in those materials. I realize that most houses do not have clay roof tile (mine does) so I removed its embodied energy from the calculations and then the lumber equaled 63% of the total.

Looking at the broader picture, here are some other points that make lumber less attractive than claimed:

• Non-lumber materials are easier to remove and require less work (energy).

• Lumber is salvaged only after all other materials have been salvaged, recycled or landfilled. This salvaging process alone involves more embodied energy than removing a cabinet, toilet or door.

• Just because lumber is in high demand does not mean there are no after-markets for the other materials.

That would be like saying the only demand for used automobiles is for BMWs. TRP offers firsthand proof of this: historically our annual lumber sales represent 25 to 30% of our total retail sales, yet sales over the past 12 months have been the highest in 28 years, and lumber sales represented only 15% of sales during that period.

• Merchandising lumber is more difficult than other materials: lumber price points vary depending upon species and age, some customers buy individual sticks and others want entire units, and each lumber sale requires different handling requirements.

Extrapolating from TRP’s own 2010 through 2020 data, only 25% of TRP projects are full deconstructions (including lumber). The rest are remodels. Of the 200 projects whose materials come to our warehouse, or are delivered to a partnering warehouse each year, only 50 include any significant quantity of lumber. This means the vast majority of deconstruction projects reclaim only fixtures.

Is lumber important in the salvage business? Of course it is, but there are outstanding sales opportunities in other materials. And, if your focus is on the environment, then energy (read carbon) per pound is important. More energy is saved through the salvage and reuse of those other materials. Finally, as any good retailer will tell you, stocking a variety of materials draws more customers and hence results in higher sales than positioning yourself as a strictly used lumber yard. That’s one reason why commercial lumber yards carry all sorts of hardware, fasteners, tools and other non-lumber items.

Footnotes * All metal is considered recycled – Otherwise virgin steel would be 13,760 BTU/pound and aluminum 97,610.

1. Stove with cooktop, 2 refrigerators, microwave, dishwasher

2. Cabinets are an enhanced wood product with metal pulls and drawer slides

3. Door knobs, hinges, faucets

4. Assumed each fixture contained equal weights of steel and glass

5. Assumed 17,600 board feet of Douglas fir (EPA estimates are 16,000 for 2000 s.f.) with a 40% salvage rate

6. Furnace, compressor and water heater

7. 3 bath sinks, 2 toilets and 1 laundry sink. Estimate of BTUs for porcelain is mine.